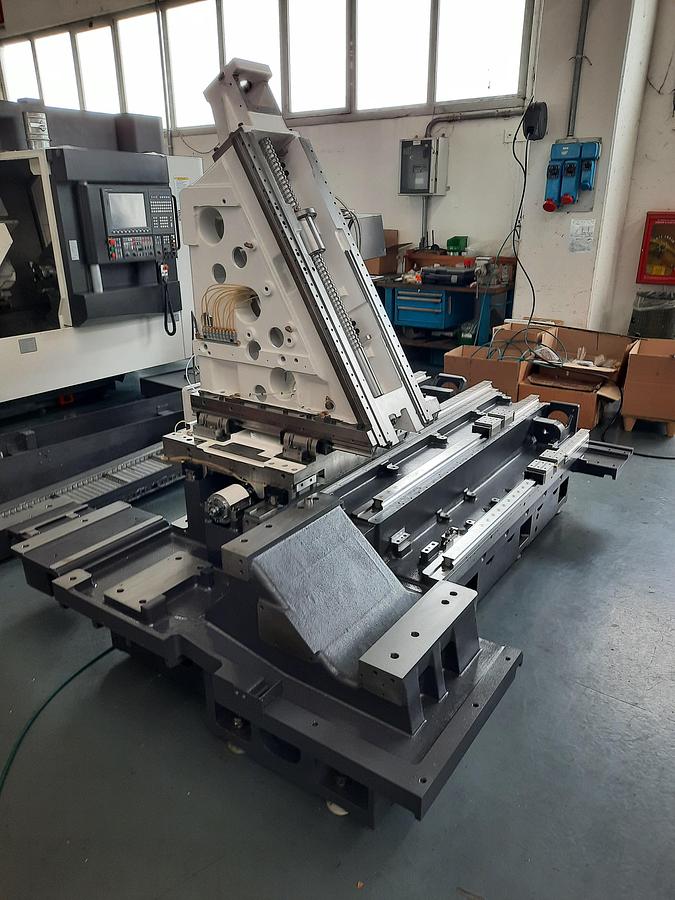

USED REFURBISHED OKUMA MULTUS B300 W LATHE

Sold

USED REFURBISHED OKUMA MULTUS B300 W LATHE

Location:Cologno Monzese, Italy

Description

The used and overhauled Okuma Multus B300 W lathe is a high precision machine for turning applications.

advanced. Equipped with an OSP P200 L CNC management, it offers a distance between the tips of 900 mm and a maximum rotating diameter

of 630 mm. The ASA 8 Big Bore main spindle reaches a speed of 3800 rpm, while the

HSK-63 milling boasts a maximum speed of 10,000 rpm. The machine supports a bar passage of 70 mm and

It has a tool magazine with 60 positions, managed randomly, with a tool change time of 2

seconds.

The Z, X, Y, W and B axis travels of 935 mm, 580 mm, 160 mm, 1000 mm and 225° respectively allow for flexibility

operational. The B-axis can be indexed accurately to 0.001°, while the rapid traverse of the X- and Z-axis is 40 m/min.

The Y-axis moves at 26 m/min, the W-axis at 20 m/min, the C-axis at 200 rpm and the B-axis at 30 rpm. The machine is designed for

ensure excellent machining capacity with maximum available power of 22/15 kW for the main spindle and

16/11 kW for the milling spindle.

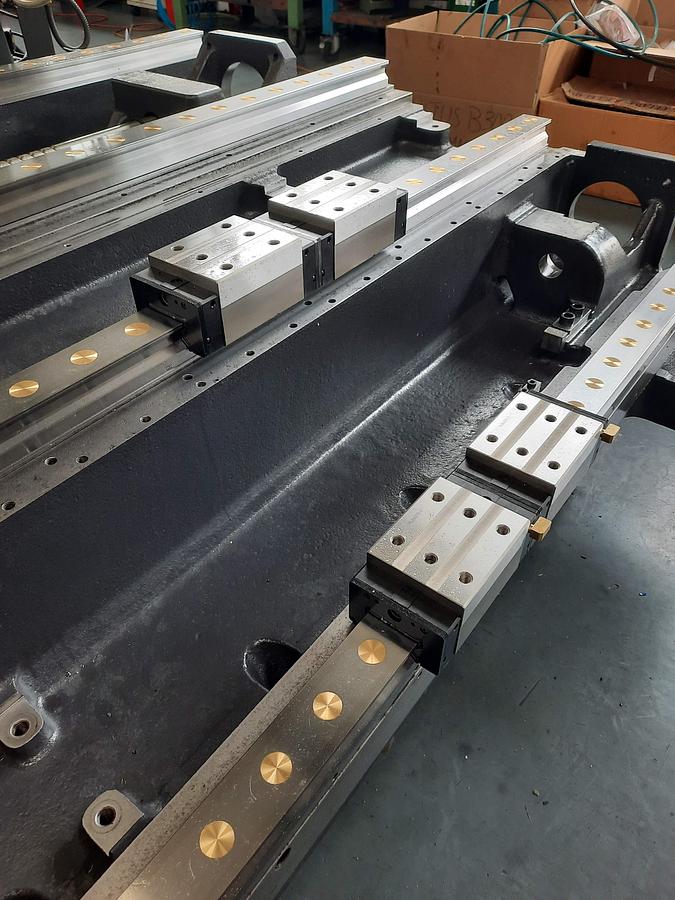

The system is enriched by several options such as the roller chip conveyor, Y-axis measuring software,

helical interpolation and other advanced functions to improve productivity and accuracy. With dimensions of

With a footprint of 4,340 x 2,257 m and a weight of 10,300 kg, this lathe is a solid option for those looking for reliability and

advanced technology in a turning plant.

Options Included:

-ASA 8 Big Bore Main Spindle

-HSK-63 milling spindle at 10,000 RPM

-60 Position Warehouse

-Shutter chip conveyor

-Double main self-centering locking pressure

-Air blow cleaning against spindle

- In-process piece measurement

-Origin shift after probing

-C-Axis Movement W version

-Y-Axis Measurement Software

-Helical interpolation

-DNC DT

Specifications

| Manufacturer | OKUMA |

| Model | MULTUS B300 W |

| Year | 2008 |

| Condition | Used |

| Stock Number | 00062 |

| GOVERNMENT UNIT | OSP P200 L |

| DISTANCE BETWEEN THE TIPS | 900 mm |

| MAXIMUM ROTATING DIAMETER ON THE PROTECTIONS | 630 mm |

| SPINDLE ATTACHMENT | ASA 8 |

| BAR PASSAGE | 70 mm |

| SPINDLE TURNS | 3800 RPM |

| NUMBER OF CONTINUOUSLY VARIABLE RANGES | 2 Ranges |

| MAXIMUM POWER AVAILABLE | 22 / 15 Kw |

| Z AXIS TRAVEL | 935 mm |

| X AXIS TRAVEL | 580mm (-20 +560) |

| Y AXIS TRAVEL | 160mm (-80 +80) |

| W-AXIS STROKE | 1000 mm |

| B-AXIS STROKE | 225° (-30° +195°) |

| B-AXIS INDEXING | 0.001 ° |

| C-AXIS DIVISIONS | 360.000 |

| RAPID ADVANCEMENTS X - Z AXES | 40 m / min |

| Y-AXIS RAPID FEED | 26 m/min |

| W-AXIS RAPID FEED | 20 m / min |

| C-AXIS RAPID FEED | 200 RPM |

| B-AXIS RAPID FEED | 30 RPM |

| MAXIMUM MILLING SPINDLE POWER | 16 - 11 Kw |

| MAXIMUM MILLING SPINDLE SPEED | 10,000 RPM |

| TOOL ATTACHMENT | HSK-63 |

| TOOL WAREHOUSE NUMBER | 60 |

| WAREHOUSE MANAGEMENT | RANDOM |

| TOOL CHANGE TIME | 2 sec |

| COUNTER-SPINDLE ATTACHMENT | ASA 6 |

| BAR PASSAGE COUNTER SPINDLE | 50 mm |

| MAXIMUM COUNTER SPINDLE SPEED | 5,000 RPM |

| MAXIMUM COUNTER SPINDLE POWER | 20 / 15 Kw |

| MAXIMUM HEIGHT OF THE MACHINE | 2,587 m |

| GROUND OVERALL DIMENSIONS | 4,340 X 2,257 m |

| MACHINE WEIGHT | 10.300 Kg |