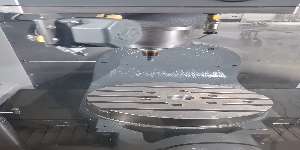

2022 HAAS UMC 500 SS

2022 HAAS UMC 500 SS

Location:Cologno Monzese, Italy

Description

Technical Features

Super-fast 5-axis CNC vertical machining center with 24″ x 16″ x 16″ (610 x 406 x 406 mm) travels, CT, 1 GB on-board memory, Dynamic work offsets and tool center point control, Early power failure detection module, Ethernet interface, HaasConnect Remote Monitoring, HaasDrop, Second home position, High-speed machining, M130 media display M-code, Remote feed handle with touchscreen display, Rigid tapping, Safety travel, WiFi connection to Haas control, 55-gallon (208-liter) coolant tank with 3/4 hp (0.6 kW) pump, Cooling unit for CNC control cabinet, Precision direct measurement system on B and C rotary axes, Top cover, Coolant flow control pump, Wireless intuitive probing system; Renishaw, 12,000 rpm spindle, BT40 taper, 30 hp (22.4 kW) vector drive; in-line direct drive, High speed side mounted tool changer, 40 taper, 30+1 tools.

The machine is supplied with a CE Declaration of Conformity and satisfies the essential safety requirements set out in the Machinery Directive.

Options:

BT OPTION

COOLANT FLOW THROUGH SPINDLE, 69 BAR

This high pressure through-spindle coolant system delivers up to 69 bar of coolant to the cutting edge for heavy cutting, higher feed rates, deep hole drilling and improved surface finish. 15,000 rpm max with through-spindle coolant enabled.

PROGRAMMABLE COOLANT NOZZLE

The programmable coolant nozzle is a multi-position nozzle that automatically delivers coolant to the cutting tool with the highest precision. The nozzle positioning is controlled by program, in order to avoid continuous settings, thus saving the operator time. The nozzle position can also be adjusted manually from the pendant control.

BELT TYPE CHIP CONVEYOR

This belt chip conveyor quickly removes chips from the machine and discharges them at barrel height. It is a useful solution for high production applications or when working with hard or abrasive materials.

AIR JET THROUGH TOOLS

The Through-Tool Air Blast option provides high pressure/high flow air through the tool to the cutting edge. Requires the TSC Through-Spindle Coolant option. Air requirements are application dependent. Available for inline spindles only.

AUXILIARY COOLANT FILTER SYSTEM

This 25 micron, two-bag filter system removes contaminants and very small particles from the coolant before they can be circulated through the coolant pump. The filter is required on machines with through-tool coolant systems when machining cast iron, molten aluminum, wood, phenolic resins and other abrasive materials.

MACHINE ANCHORING KIT

Machine Anchoring Kit; includes mounting clamps, hardware, anchoring epoxy, pipe brush, drill bit

1″ for hammer and machine anchor template.

Specifications

| Manufacturer | HAAS |

| Model | UMC 500 SS |

| Year | 2022 |

| Condition | Refurbished |

| Stock Number | 00004 |

| X axis travel | 610 mm |

| Y axis travel | 406 mm |

| Z axis travel | 406 mm |

| Distance from spindle nose to table max. | 508 mm |

| Distance from spindle nose to table min | 102 mm |

| Spindle power | 22.4 Kw |

| Maximum spindle speed | 12,000 RPM |

| Maximum torque | 122.0 Nm at 2.000 Rpm |

| Spindle connection | BT 40 |

| B-Axis Stroke | from +120° to -35° |

| Maximum speed Axis B | 179° per second |

| Braking torque Axis B | 1220 Nm |

| C-Axis Stroke | 360 ° |

| Maximum speed C-axis | 179° per second |

| C-Axis Braking Torque | 1220 Nm |

| Maximum piece rotation | 457 mm |

| Table diameter | 400 mm |

| Maximum weight on the board | 226.8 Kg |

| T-slot width | 16.00 mm |

| Number of T-slots | 5 |

| T-slot centre distance | 63 mm |

| Rapid advances X - Y - Z axis | 30.5 m per minute |

| Tool change | SMTC |

| Tool change capacity | 30+1 |

| Maximum tool diameter | 64 mm |

| Maximum diameter of adjacent empty tool | 127 mm |

| maximum tool length | 305 mm |

| Maximum tool weight | 5.4 Kg |

| Tool change time | 1.80 seconds |